Enter any two known values and press calculate to solve for the others.

Temperature management is critical in many industries, from medical and aerospace to semiconductor and industrial manufacturing. Selecting the right temperature sensor can significantly impact accuracy, efficiency, system performance, and safety while also protecting assets. Birk Manufacturing offers various types of thermal sensors—RTDs, thermocouples, thermistors, and thermostats—each used for different applications and environments.

In this blog, we’ll outline these sensors so you know a bit more about the options available to you. Luckily, you don’t need to be an expert because our engineers are! The information below is a guide to understanding some basics of thermal management.

RTD Sensors: Precision and Stability for High-Accuracy Applications

How They Work:

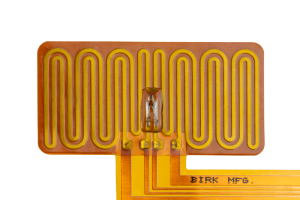

Resistance Temperature Detectors (RTDs) operate based on the principle that a metal’s electrical resistance changes with temperature. The resistance vs temperature relationship is well known and repeatable over time. RTD’s provide accurate and repeatable measurements across a broad temperature range (-150°C to 300°C)*. Birk RTD sensors are thin-film and made by depositing a thin layer of metal—platinum, nickel or copper— onto a ceramic substrate into a known resistance pattern.

*For temperatures outside of this range, please consult with a Birk Engineer about other options.

Key Benefits:

Common Applications:

|

|

Learn more about Birk’s RTD sensors here.

Thermocouple Sensors: Durable and Quick-Responding for Extreme Temperatures

How They Work:

A thermocouple consists of two wires made from different metals joined at both ends. When the junction of the two metals is heated or cooled, a voltage is produced that can be correlated back to the temperature.

Key Benefits:

Common Applications:

|

|

Learn more about Birk’s Thermocouple sensors here.

Thermistors: High-Sensitivity Sensors for Narrow Temperature Ranges

How They Work:

Thermistors are highly sensitive temperature sensors made of materials whose resistance changes with temperature. This resistance variation is measured to determine temperature.

Birk offers two types:

Key Benefits:

Common Applications:

|

|

Thermostats: Cost-Effective, On/Off Temperature Control

How They Work:

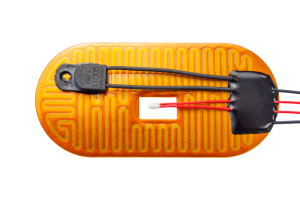

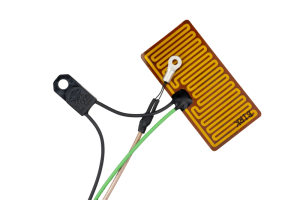

Thermostats use a bimetallic disc that bends as temperature changes, triggering a switch to turn a heater on or off at a predetermined set point. They are commonly used as fail-safes for temperature-sensitive applications.

Key Benefits:

Common Applications:

|

|

The expertise you need

We hope you learned a little from the information above, but navigating the complexities of thermal management doesn’t have to be overwhelming. That’s what Birk Manufacturing is here for.

Our team of engineers specializes in designing and integrating the right thermal solutions for your specific application, ensuring optimal performance, reliability, and efficiency. Whether you need precision, speed, durability, cost-effective control or a combination of them all, Birk has the expertise to guide you to the best solution for your project.

What truly sets Birk apart from the rest is our ability to offer all these sensor types in a variety of packaging options, such as small polyimide tubes, probes, bolts, ring terminals and more. Birk can also incorporate all sensor types into any heater assembly via surface mount, wiring harness, under the cover, in epoxy, etc.

Contact us today to discuss your needs!