Enter any two known values and press calculate to solve for the others.

Today, localized heating is key to the performance of industrial applications. To achieve this, manufacturers use various types of flexible heating elements. These heating elements are made of different materials and can be fully customized to meet the thermal transfer requirements of an application. Silicone rubber, polyimide, mica, and butyl are a few of the popular materials used for flexible heating elements. The heating elements come in two forms: etched foil elements and wire-wound elements. With so many variations, the selection may be difficult, but this post offers tips on the selection of flexible heating elements for your applications.

In order to select a flexible heating solution, one must understand their differences. This section describes the key differences across all variables.

Wire-Wound Elements: These heating elements feature a resistance wire of a specific diameter and contain a single strand or multiple strands. If multiple strands are used, they are woven together and placed on a fiberglass core. The wires are evenly spaced and wound in a specific pattern on every layer of a substrate. The wire is vulcanized and placed on the silicone rubber or neoprene substrate.

Wire-wound heaters are typically found in dynamic applications. They can withstand abrasive forces and can be much larger than an etched foil heater.

Etched Foil: In recent years, etched foil flexible heaters have gained immense popularity. These flexible heaters have no wire; rather, they look like printed circuit boards featuring thin alloy metals. The thin alloy metals are acid etched on the substrate, with widths varying from 0.005″ to 0.10″. The foil used is very thin, allowing etched foil heaters to be extremely thin and lightweight.

Etched foil heaters are typically found in more static applications where size and weight can be a big factor, but they can also be made denser for the necessary application. These heaters have rapid heat-up and cool-down capabilities, as well as high watt densities.

![]()

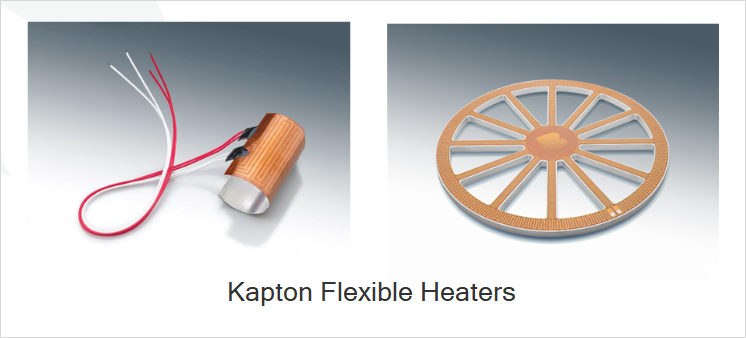

Knowing the differences between different types of materials and heater designs will help, but it is equally important to source them from a trusted manufacturer. Birk Manufacturing is one of the leading manufacturers of etched foil flexible heaters in the US. The company specializes in silicone rubber, mica, and Kapton® flexible heaters. They are the only manufacturer specializing in butyl rubber flexible heating solutions. For more information on these flexible heaters and other details, you can get in touch with the team by phone at 860-739-4170 or by email at sales@birkmfg.com.