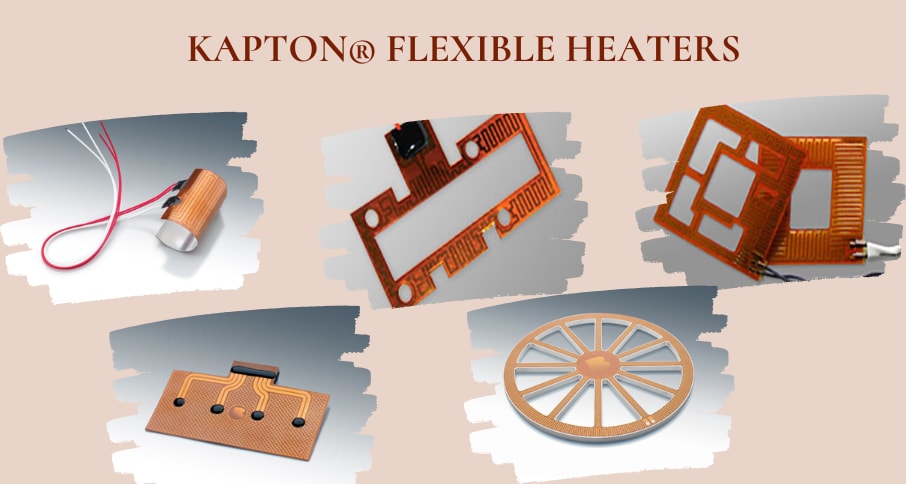

Kapton® heaters are a popular type of flexible heaters used in industries such as medical, electronics, aerospace, etc. Kapton® heating solutions are considered the best alternative to mica heaters and silicon heaters in various surface heating applications. Why? In order to understand Kapton® flexible heaters and their applications, it is important to know about the Kapton® material. This post introduces you to the Kapton® material, Kapton® heaters, and their technical capabilities.

An Overview of Kapton® and Kapton® Flex Heaters

Kapton® is a polyimide film manufactured by DuPont, and it offers a wide range of chemical, physical and mechanical properties. This material exhibits great stability across temperatures ranging from −452°F to 752°F, making it an ideal choice for heaters in applications that may be exposed to a wide range of ambient temperatures.

Thin films of this polyimide material are etched with foil circuits to manufacture Kapton® heaters. Thus, these flexible heaters are also known as etched foil Kapton® flexible heaters. The polyimide sheets are 0.003 to 0.01 inches thick and offer excellent dielectric qualities. Kapton® thin flexible heaters are capable of providing 5000 volts of dielectric per 0.001 inches of thickness.

Thin film Kapton® heaters consist of foil elements. Let us discuss the construction of etched foil Kapton® flex heating elements.

-

- Construction of Polyimide Flexible Heating ElementsFirst, the circuit is designed using CAD software. Then a thin nickel-based alloy foil, used as a resistance element, is etched onto the polyimide material in the proper circuit pattern.

These Kapton® heating elements are then placed between thin polyimide sheets and bonded. The Kapton® flexible heaters can be bonded using two different methods:

-

-

- FEP Teflon thermos flow bonding

- Thermos flow acrylic bonding.

-

Along with the types of bonding, the properties of Kapton® contribute to the performance of Kapton® polyimide film heating elements. Let us discuss the properties of Kapton® that make these flexible heaters appropriate for industrial applications.

Properties of Kapton®

The significant properties of Kapton® flexible heaters are listed below.

-

- Temperature Tolerance: Generally, Kapton® heaters can withstand temperatures from -300°F (-185°C) to 392°F (200°C). The FEP bonded Kapton® polyimide film heaters can withstand temperatures up to 500°F (260°C). This temperature tolerance range makes them an ideal choice for cryogenic environments and high-temperature applications.

- Dimensional Stability: The dimensional stability of Kapton® flex heaters is excellent at both low and high temperatures.

- High Watt Density: The watt density of polyimide flexible heating elements is ≤3.0 Watt/cm2. However, depending on the backing, the watt density may differ. Due to the shaded watt density, even distribution of heat takes place in these flexible heaters.

- High Dielectric Strength: The dielectric strength of Kapton® heaters is about 197 kV/mm. These heaters offer great insulation properties.

- Lightweight and Thin Construction: Polyimide films are lightweight and transparent in nature. Being lightweight, the Kapton® flex heaters can be installed on any industrial system.

- Flexible Installation: The polyimide flexible heaters can be attached to the surface using pressure-sensitive adhesives, mechanical attachments, or self-fusing tapes.

- Can Withstand Environmental Elements: Kapton® foil heaters can resist multiple environmental elements like chemicals, moisture, radiation, vibrations, and fungal growth.

Now that you understand how Kapton® flexible heaters are constructed and are familiar with their technical properties, you should consider buying high-quality Kapton® flexible heaters. To ensure their quality, you should source your heaters from reliable Kapton® heating element manufacturers such as Birk Manufacturing, Inc. The company offers ISO9001, ISO13485, and AS9100-certified industrial heaters. Kapton® flexible heaters are one of their highly sought after products.