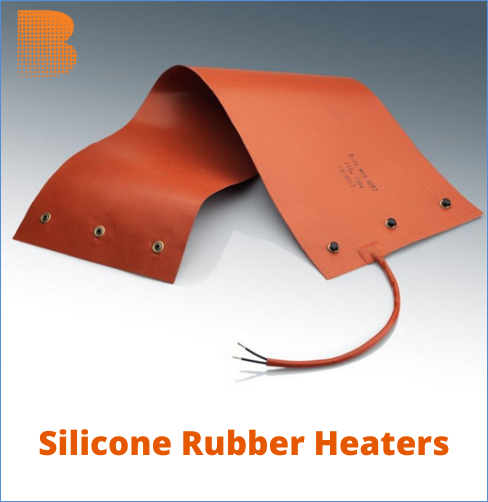

Silicone rubber heaters are widely used in applications where improved heat transfer rates are needed. These heaters are lightweight, extremely flexible, and thin, which makes them popular across industries. Most experienced silicone rubber heater manufacturers can offer them in custom specifications to meet your application requirements. However, this information is not enough to make a purchase decision. The previous post introduced you to the benefits offered by these heaters. This section of the post focuses on their types, mounting methods, and applications. Gaining an in-depth understanding of these areas will certainly help in the decision-making process.

Types of Silicone Rubber Flexible Heaters Based on Elements

Silicone rubber flexible heaters are usually offered in wire-wound element construction or etched foil element construction. The following pointers will help you understand them better.

- Etched Foil Element Construction: Etched foil flexible silicone heaters feature a large flat surface area, which contributes to their exceptional heat transfer capabilities. Etched foil flexible silicone heaters are widely preferred over wire-wound elements because they have a long operating life. They ensure uniform heat transmission at higher watt densities.

- Wire-Wound Element Construction: Silicone rubber heaters comprising wire-wound elements can withstand repeated flexing. The flexing has no effect on its performance and shape. Complex shapes can be easily achieved in wire-wound elements, and it is quite common to find 3D silicone heaters with wire-wound element construction. Wire wound construction is commonly recommended for prototype building and mid-sized production volumes.

Birk Manufacturing, Inc. is one of the most experienced silicone rubber heater manufacturers in the US. The company offers silicone rubber heating solutions in several customized shapes and sizes to meet your application requirements.

Mounting Methods of Silicone Flex Heaters

Silicone rubber heaters can be mounted on flat or curved surfaces. Their designs will vary slightly according to the mounting methods chosen. Hence, it is important to specify the right mounting method to the manufacturer when specifying the design requirements of silicone rubber heaters. The following are a few common mounting methods for silicone rubber heaters.

- Pressure Sensitive Adhesive (PSA): Pressure sensitive adhesives are an ideal choice for applications that demand economical and quick installations. You can peel off the backing and place the heater in the required position to create a uniform and even bonding with the surface. PSA is not recommended for applications that may be subjected to temperatures as high as 400 degrees Fahrenheit on silicone rubber. It is also not recommended for curved surfaces.

- Mechanical Fasteners: These fasteners are generally used with wire-wound flexible heaters. Boot hooks, grommets, and latch fasteners are a few common types of mechanical fasteners.

- Field Applied Adhesives or Vulcanization: These adhesives ensure maximum heat transfer, and are chosen when long-term storage and strong bonding is expected. They are available as red room temperature vulcanizing (RTV) silicone adhesive and white room temperature vulcanizing (RTV ) silicone adhesive. The red RTV has a higher temperature limit than the its’ white onecounterpart.

- Silicone Contact Cement Kit: This is a two-part adhesive kit comprising a catalyst and a resin. The kit is commonly recommended for applications where the silicone rubber heaters need to be cemented to customized parts.

Applications of Silicone Rubber Heating Elements

Silicone rubber heating elements are used in the following applications owing to the benefits that they offer. Here are some application areas:

- Blood analyzers

- Respiratory therapy units

- Hydrotherapy units

- Wafer processing equipment

- Food holding and warming cabinets

- Satellite and communication equipment

- Hydraulic equipment

- Laser printers

- Photo processing equipment

- Semiconductor processing equipment

If you are seeking quality flexible silicone heating elements for your industrial applications, it is important to partner with a trusted and experienced manufacturer like Birk Manufacturing. The company regularly designs and develops custom flexible silicone heaters for all the aforementioned applications and more. The company’s experts will work closely with you to understand your application requirements and offer you appropriate solutions.