Enter any two known values and press calculate to solve for the others.

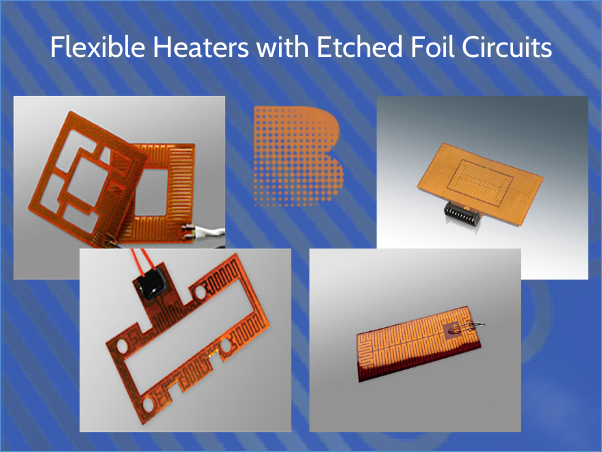

Flexible heaters allow either uniform heating or focused heating of an object. They can be bent or molded depending upon the shape and size of the object. Kapton® heaters, along with several other styles of flexible heaters, contain an etched foil element. A metal foil or sheet is flattened and etched to create a favorable circuit pattern. This etched circuit is the conductor material commonly used in flexible heaters. This post discusses the significance and benefits of using these etched foil circuits in heating systems.

An etched foil circuit element consists of a thin metal foil, usually made of aluminum, nickel, steel, or copper alloys. This foil is embedded between two insulating layers, which are usually made of silicone, polyimide, mica, or another material. These layers protect the circuit and then can be bonded or vulcanized directly to the heat sink/object.

These types of flexible heaters are commonly used in temperature-sensitive applications; hence, they come with thermostats, temperature sensors such as thermocouples and RTDs, and fuses for efficient temperature control. These flat, surface-bound heaters are not only user-friendly but also offer several other benefits.

Etched foil circuit heaters are fully customizable. This is a beneficial factor, as you can customize them according to your specifications. Here are some other benefits of etched foil heating solutions:

Birk Manufacturing, Inc. offers various types of custom thermal systems, including flexible heaters that are useful across different industries. The company offers customizable etched foil circuits to meet your specific application requirements.