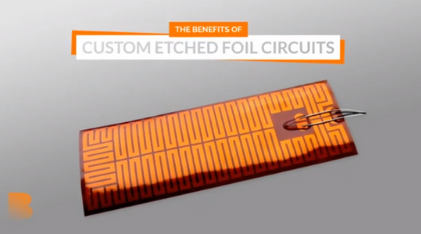

Etched foil circuits are important components in flexible electronics and appliances. These circuits can be found in flexible heaters, which are used in a variety of industrial applications such as medical incubators and genetic testing systems; aerospace battery packs and navigation equipment, and semiconductor acid heating in wafer processing baths.

Needless to say, there are a variety of applications that have specific requirements for the etched foil circuits. Hence, custom etch foil circuits design and manufacturing solutions are required.

Custom Etch Foil Circuit Solutions

Manufacturers can meet specific industrial application requirements by providing a variety of custom solutions.

- Holes and Cutouts: These days, heaters are designed using a three dimensional approach. The designer will create the circuits in various shapes and sizes and then generate unique holes and/or cutouts that will accommodate the etched circuit into the requisite part. This design helps the heater to provide balanced heating throughout the in applications.

- Multilayer Circuits: Many applications such as aerospace and defense require large surface areas to be heated at the same time. In this requirement, one large circuit will not be enough to meet the application need. The solution for this is custom multilayer circuits, which combines two or more circuits together. This allows the heater to achieve maximum watt density throughout the surface area. Sensor flex circuits are also available to achieve optimal heat in required areas.

- Sensors and Fuses: While the circuit supports the heating process in an application, manufacturers also have to ensure that the circuit does not provide excess heat, which can damage the surface and appliance. To prevent this, a variety of sensors or fuses can be added to the circuit assembly to control heat and maintain temperatures. A few commonly used examples of such sensors are thermostats, thermocouples, and RTDs.

- Voltage Regulators: Another way to maintain the amount of heat is to provide balanced voltage. For flexible heaters, this can be accomplished by using voltage regulators. These regulators are designed to maintain a constant voltage level, which allows for balanced power and heat distribution.