Enter any two known values and press calculate to solve for the others.

Birk Manufacturing designs thousands of wire and etched-foil circuits each year to meet the specific needs of our customers. We can offer our customers the many features highlighted below.

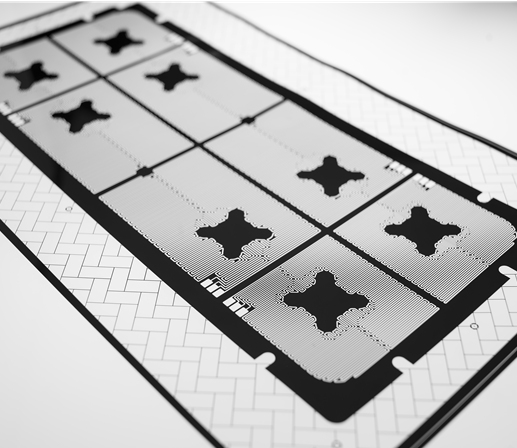

Holes and Cutouts:

Many times, heaters need to fit around holes and cutouts. Either etched foil or wire circuits can be used to provide heating of only the desired surface area.

Multi-layer Circuits:

Often, we need to maximize surface area to spread the watt density. Multi-layer circuits can be used to fit a high resistance in a small area by putting two circuits in a series. A multi-layer circuit also allows us to put a sensor flex circuit on top of the heater circuit to maximize the heated area.

Sensors and fuses:

To control heat and temperature limits properly, thermostats, RTDs, thermocouples, thermistors, solid state sensors and fuses are strategically placed within a circuit to achieve the best operating thermal system.

Various Terminations:

Birk can offer many different terminations, such as soldered connections, welded connections, connectors, pins and zero-insertion-force connections.

Shaded Watt Density:

Different heat intensities in the same circuit can provide even heat across an entire area, and can compensate for cool heat-sink edges.

Dual Voltage Circuits:

A single heater can be designed to operate on more than one voltage through the inclusion of dual circuits with three leads.

Resistance Taps:

Since the heater circuit is a resistor, taps can be taken anywhere along that circuit to provide a given voltage to an LED or other component that requires other than line voltage.

Flex Circuits for Sensors:

Sensors are generally located within a heated area. Non-heated flex circuits can be built into the circuit design to carry sensor signals to instruments.